Intro to Digital Knitting

What's knitting? and what's cool about it?

Hey there! Welcome to my first-ever and WIP post. I will try to convince you why I use knitting as my main medium for research to create wearable devices. When I started as a graduate student, it took me a minute to shake off the idea that knitting was just a hobby. But knitting didn’t take long to captivate me—its mechanical traits and the incredible potential to tweak geometries and properties really drew me in. Knitting intersects with physics, computer graphics, topology, and fiber science, making it a fascinating and powerful tool for innovation and research.

Intro

Knitting, at its core, involves the creation of a matrix of interlocking loops made from a continuous thread of yarn. This process of forming loops can be done by hand, with a manual machine, or through a digital knitting machine. Despite the different tools, the fundamental mechanics of loop formation remain the same across all methods.

In machine knitting, different stitch types (or loops) are created based on the various operations of the needles. The process typically begins with a feeder carrying the running thread across a bed of needles. When a needle is raised, the latch opens to release the old loop and engage with the new yarn. Depending on the needle’s position, it can either form a new loop, tuck the yarn into the needle, or skip receiving the new yarn altogether. These operations result in three primary stitch types: knit, tuck, and miss.

The elasticity of knitted fabrics arises from the geometry and topology of the stitches, which allow the fabric to stretch and bend in ways that are not possible with the yarn alone. This emergent behavior results from the interplay between stitch patterns and yarn properties. If you are interested in approaching knitting from its topology and its impact on mechanical behavior, you might find Elisabetta Matsumoto’s and Samuel Poincloux’s work fascinating.

For those who are new to knitting, now would be a great time to check out the instructional posts by Jim McCann, which provide a helpful introduction to knitting. The interactive knitting simulation in one of his videos at around the 4-minute mark could be especially helpful.

Digital Knitting

Digital knitting, unlike manual knitting, leverages software to translate pixel-based designs into machine instructions that knitting machines can understand. Several manufacturers provide digital knitting machines, including Kniterate, STOLL, and Shima Seiki, each with its own proprietary software to facilitate the digitization of designs into machine-compatible operations. This digital approach allows for other fabrication tools to aid designers with the design, compile the design to machine-level operations and more.

Unless otherwise specified, my work is typically done on a Shima Seiki SRY123 machine, with designs created using the Apex 3 software. Similar to Fusion or CAD, KnitPaint is a feature within Apex 3 that allows users to design and export files that the knitting machine can interpret. As of August 2024, KnitPaint can open .SKNP files and export .000 files to the knitting machine. This process is comparable to opening .STEP or .OBJ files and exporting .STL files for a 3D printer.

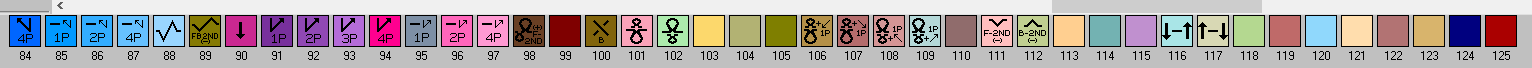

I took the liberty of referring to individual pixels as chips. These chips can sometimes be given specific instructions to manipulate needles and feeders, while at other times, they just serve as placeholders.

I’ll explore this further in my next post, which will focus on KnitPaint. Stay tuned!

Machine Parts

The parts of a machine can differ depending on the model and might be called by different names. You’ll find these terms helpful when dealing with machine errors, programming in KnitPaint, or using Knitout

- Tension mechanism: Tension mechanisms control the tension of the yarn as it is fed through the machine. Commonly these include tension disks, tension springs, and tension arms, which adjust the tightness or looseness of the yarn as it moves from the yarn cone to the needles.

- Front panel: Located at the bottom of the SRY machine, the front panel houses most of the take-down interfaces. You will need to push the knob to open the panel to access it.

- Loop presser: The two fly-out beds include mechanical components that assist in forming stitches by applying downward pressure on the loops of yarn.

- Sinkers: While the SRY machine doesn’t have sinkers (bummer), they are typically thin metal plates in knitting machines. They hold fabric down and maintain tension on loops as needles move up and down, ensuring that stitches form correctly.

- Bed: The bed is made up of a steel body with grooves where the needles slide with their hook and butt turned upward. The grooves guide the needles while sliding.

- Carriage: A plastic enclosure that runs along the rails and needle beds. The carriage manipulates the position of needles, moves the carriers, and holds the position of the carriers through plungers.

- Plunger (pin stop): Located on the top part of the carriage (usually not visible), the plungers grab the carrier to knit the yarn. If you want to stop knitting midway, check if the plungers are pushing the feeders before bringing them back home.

- Yarn carrier or feeder: I noticed that feeder and carrier are used almost interchangeably. But you shouldn’t confuse them with carriage. Feeders are where the machine holds the thread to then traverse and hook onto the needles. They are located in the carriage above the needle bed. SRY123 uses two types of feeders: swing (a.k.a KSW) and non-swing feeders. Here’s a little catch, by configuring the plunger in KSW carriers in a specific way you’ll force the plunger to cam out left/right/center. This means KSW feeders can be configured as N feeders as well.

- N: Normal

- NPL: Normal for Plating

- S: SSUPY (elastic)

- KSW1: Swing Kick Yarn Feeder 18mm (for 8, 10, 12, and 14 gauge machines)

- Default for Shima SRY 123 gauge

- KSW2: Swing Kick Yarn Feeder 14mm (for 16 and 18 gauge machines)

- KSW3: Swing Kick Yarn Feeder 24mm (for 7 gauge machine)

- KSW0: Swing Kick Yarn Feeder with yarn feeder fixed block

- DY: Draw yarn (nylon)

- INLY: Inlay knitting

- YG: Yarn guide

- Rail or yarn feeder guide track: SRY123 has four rails with two sides (8 sides). Feeders suspending from the front side of the first rail (from front to back) are Feeder 1. Feeders 1 and 2 are suspended from the 2nd rail, and so on. This system becomes important when you’re processing. For instance, Feeder 8 is a feeder hanging on the backside of the 4th rail, so the rail is farthest from you. Some feeders, such as Feeder 8, have a specific feeder design to serve certain roles and do not thread other materials.

- Feeder 8 (4th rail): Nylon is in the lead, with elastic in the trail.

- Feeder 4 (2nd rail): This feeder has pink put-through holes and is used for plating.

- Stitch cam settings or cam settings: These are how to manipulate your yarns’ stitch length according to your feeders. What numbers’ stitch lengths you can manipulate are specified in your option lines. Intuitively, if you have thicker **yarn, you may want to use longer stitch lengths, while with thinner yarn, you can use smaller stitch lengths. You can choose how tight or loose you’d like your structure to be.

- Takedown (comb and rollers): Imagine knitting a swatch without a weight pulling it away from the bed. The swatch will scrunch. Rollers and a comb in the machine grab the swatch and pull it down, so the swatch is always under constant tension.

- Cutter and gripper: cutter and gripper go hand in hand. There are, in total, four grippers and two cutters; two grippers and a cutter on the left and right of the needle beds. You can control grippers and cutters with option line R8 by putting #31 chip on the side, and R10 with #41 chip.