Publications

publications by categories in reversed chronological order.

2026

- IEEE HAPTICS

Curvature-Aware Calibration of Tactile Sensors for Accurate Force Estimation on Non-Planar SurfacesLuoyan Zhong, Heather Jin Hee Kim, Dylan P. Losey, and 1 more authorHaptics Symposium, Reno, Nevada, USA, 2026

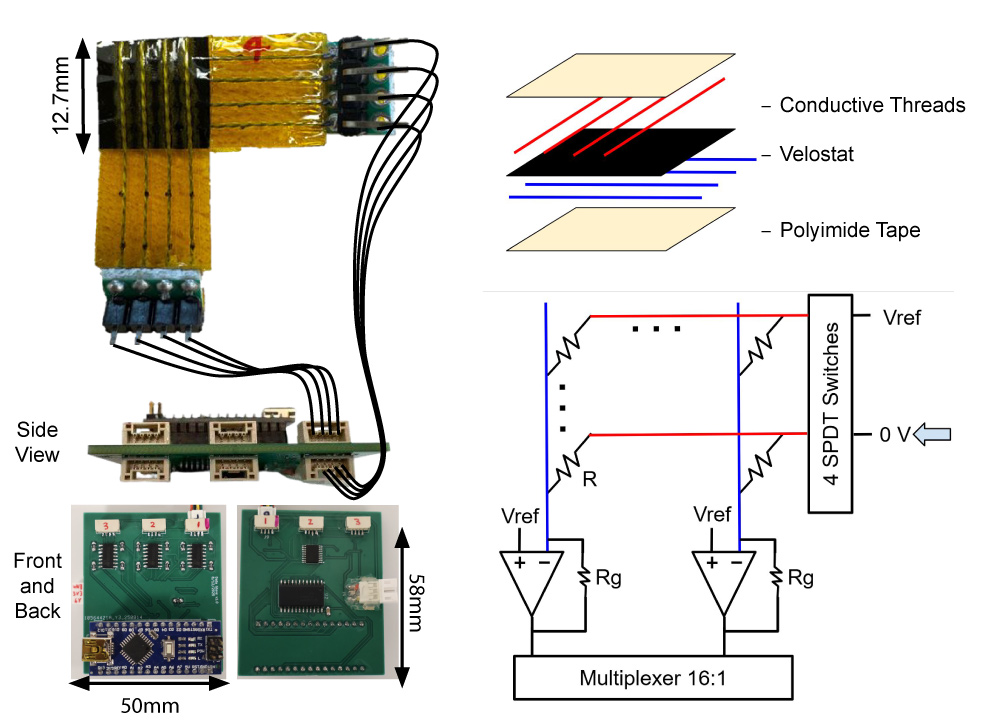

Curvature-Aware Calibration of Tactile Sensors for Accurate Force Estimation on Non-Planar SurfacesLuoyan Zhong, Heather Jin Hee Kim, Dylan P. Losey, and 1 more authorHaptics Symposium, Reno, Nevada, USA, 2026Flexible tactile sensors are increasingly used in real-world applications such as robotic grippers, prosthetic hands, wearable gloves, and assistive devices, where they need to conform to curved and irregular surfaces. However, most existing tactile sensors are calibrated only on flat substrates, and their accuracy and consistency degrade once mounted on curved geometries. This limitation restricts their reliability in practical use. To address this challenge, we develop a calibration model for a widely used resistive tactile sensor design that enables accurate force estimation on one-dimensional curved surfaces. We then train a neural network (a multilayer perceptron) to predict local curvature from baseline sensor outputs recorded under no applied load, achieving an R^2 score of 0.91. The proposed approach is validated on five daily objects with varying curvatures under forces from 2 N to 8 N. Results show that the curvature-aware calibration maintains consistent force accuracy across all surfaces, while flat-surface calibration underestimates force as curvature increases. Our results demonstrate that curvature-aware modeling improves the accuracy, consistency, and reliability of flexible tactile sensors, enabling dependable performance across real-world applications.

@article{DataGlove, author = {Zhong, Luoyan and Kim, Heather Jin Hee and Losey, Dylan P. and Nunez, Cara M.}, title = {Curvature-Aware Calibration of Tactile Sensors for Accurate Force Estimation on Non-Planar Surfaces}, year = {2026}, publisher = {Institute of Electrical and Electronics Engineers (IEEE)}, journal = {Haptics Symposium}, keywords = {tactile sensing, flexible sensor, curvature, calibration model}, location = {Reno, Nevada, USA}, eprint = {arXiv:2510.25965}, } - ACM TEI

PileUp: A Tufting Approach to Soft, Tactile, and Volumetric E-Textile InterfacesSeoyoung Choi, Rashmi Balegar Mohan, Heather Jin Hee Kim, and 2 more authorsIn Proceedings of the Twentieth International Conference on Tangible, Embedded, and Embodied Interaction, Chicago, Illinois, USA, 2026

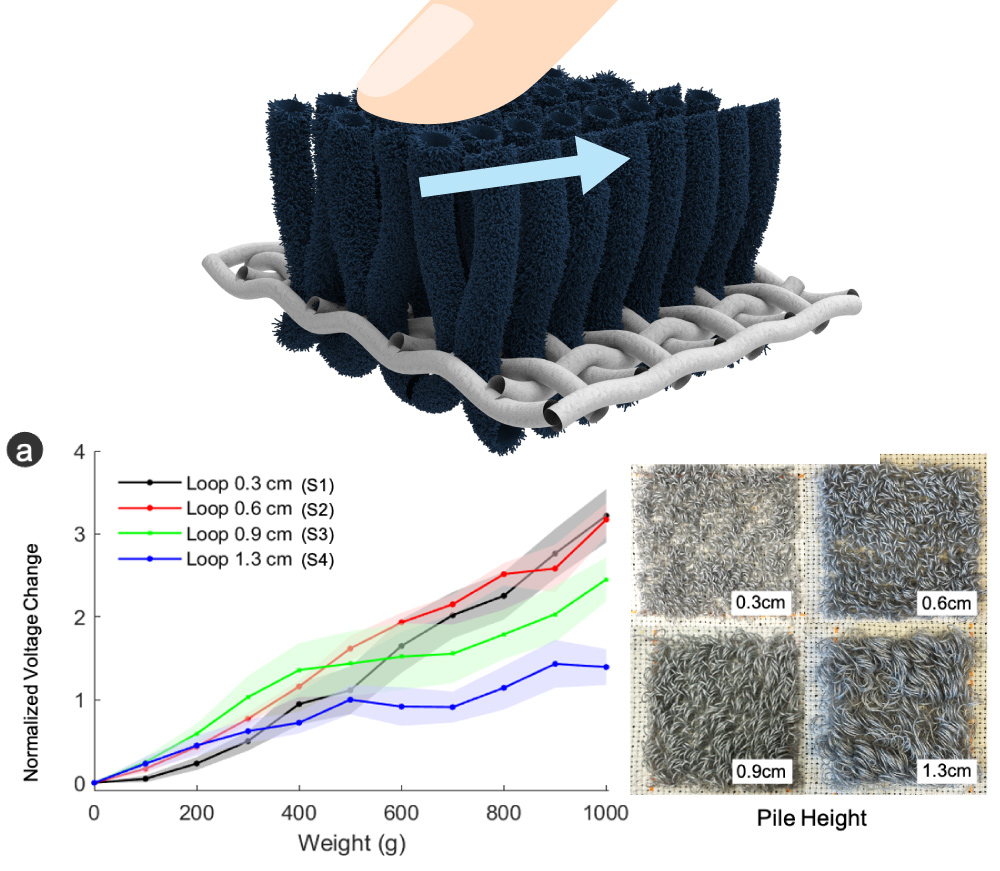

PileUp: A Tufting Approach to Soft, Tactile, and Volumetric E-Textile InterfacesSeoyoung Choi, Rashmi Balegar Mohan, Heather Jin Hee Kim, and 2 more authorsIn Proceedings of the Twentieth International Conference on Tangible, Embedded, and Embodied Interaction, Chicago, Illinois, USA, 2026We present PileUp, a tufted pile e-textile sensing approach that offers unique affordances through the tactile expressiveness and richness of its continuous, threaded-volume construction. By integrating conductive yarns in looped or cut pile forms, PileUp transforms soft 3-dimensional textiles into multimodal sensors capable of detecting mechanical deformations such as pressure, bending, and strain, as well as environmental conditions like moisture. We propose a design space that outlines the relationships between texture, form factor, and sensing affordances of tufted textiles. We characterize electrical responses under compression, bending, and strain, reporting sensor behaviors. To demonstrate versatility, we present three application scenarios in which PileUp sensors are seamlessly integrated into soft fabrics: a meditation rug with multi-zone sensing, a fleece sleeve that detects arm motion, and a moisture-sensing wall art. Our results establish tufting as an accessible yet expressive fabrication method for creating integrated sensing textiles, distinguishing our work from traditional flat textile sensors.

@inproceedings{PileUp, author = {Choi, Seoyoung and Balegar Mohan, Rashmi and Kim, Heather Jin Hee and Ha, Jisoo and Jo, Jeyeon}, title = {PileUp: A Tufting Approach to Soft, Tactile, and Volumetric E-Textile Interfaces}, year = {2026}, publisher = {Association for Computing Machinery}, address = {New York, NY, USA}, url = {https://arxiv.org/abs/2511.21000}, doi = {10.1145/3731459.3773333}, booktitle = {Proceedings of the Twentieth International Conference on Tangible, Embedded, and Embodied Interaction}, keywords = {Tufting, Pile textiles, Tactile sensing, Humidity sensing, E-textiles, Textile sensor}, location = {Chicago, Illinois, USA}, series = {TEI '26} }

2024

- ACM IMWUT

MediKnit: Soft Medical Making for Personalized and Clinician-Designed Wearable Devices for Hand EdemaHeather Jin Hee Kim, Narjes Pourjafarian, Arhan Choudhury, and 2 more authorsIn Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies, Melbourne, Australia, 2024

MediKnit: Soft Medical Making for Personalized and Clinician-Designed Wearable Devices for Hand EdemaHeather Jin Hee Kim, Narjes Pourjafarian, Arhan Choudhury, and 2 more authorsIn Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies, Melbourne, Australia, 2024Current rapid prototyping in medical domains relies on rigid 3D-printed materials, lacking flexibility, customization, and clinician-led input. This paper introduces MediKnit, a novel approach for the fabrication of soft medical devices, addressing critical limitations in existing design processes for medical devices. MediKnit provides a design tool empowering clinicians to personalize fabric-based devices for hand edema. This tool allows clinicians to adapt the design to individual patients’ demands, thereby enhancing the overall effectiveness of therapy. The MediKnit device created by this tool consists of a machine-knit glove with active compression, which is programmable through a custom PCB. This device facilitates the mobilization of edema. To illustrate the practical implementation of our approach, this paper presents case studies involving six patients experiencing hand edema. The results demonstrate the adaptability and feasibility of our process for developing soft medical devices, highlighting its potential to broaden accessibility, facilitate personalized solutions, and empower clinicians as active medical makers.

@inproceedings{mediknit, author = {Kim, Heather Jin Hee and Pourjafarian, Narjes and Choudhury, Arhan and Stilling, Joan and Kao, Cindy Hsin-Liu}, title = {MediKnit: Soft Medical Making for Personalized and Clinician-Designed Wearable Devices for Hand Edema}, year = {2024}, isbn = {}, publisher = {Association for Computing Machinery}, address = {New York, NY, USA}, url = {https://dl.acm.org/doi/10.1145/3678504}, doi = {10.1145/3678504}, booktitle = {Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies}, articleno = {110}, numpages = {30}, keywords = {Medical making, Design tool, Textile-based device, Compression device, Hand edema, Robotic textiles, Fabrication, Workflows, Case study, User study}, location = {Melbourne, Australia}, series = {IMUWT '24}, } - DISSERTATION

Leveraging Fabric Substructure Variations of Actuator-Integrated Robotic Textiles for Wearable ApplicationsHeather Jin Hee KimIn Press, 2024

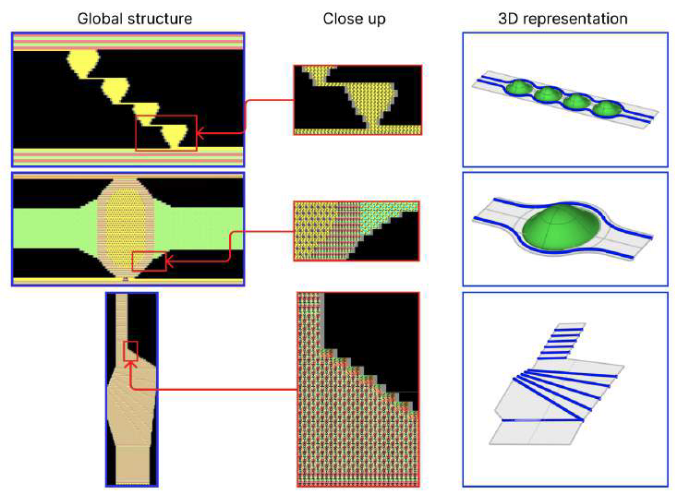

Leveraging Fabric Substructure Variations of Actuator-Integrated Robotic Textiles for Wearable ApplicationsHeather Jin Hee KimIn Press, 2024Wearable devices have evolved significantly, progressing from simple touch sensors to advanced hardware like exoskeletons, hearing aids, and space suits. These devices augment how individuals interact with their surroundings and enhance physical capabilities. Despite their effectiveness, many rigid wearable devices, characterized by gears and motors, struggle to adapt to the human body and target specific areas of the body. The emerging field of robotic textiles focuses on developing thin fabric substrates infused with actuation, variable stiffness, and sensing capabilities. The field distinguishes itself from conventional wearable technologies and soft robotics by harnessing components in fiber forms and leveraging textile manufacturing processes. The bulk characteristics of these textiles are dependent upon the primary fabric structures, whether knitted or woven. Digitally knitted substrates, in particular, offer a highly dense programmable area. Their doubly periodic structure, with each stitch configurable for different elasticities, therefore offers superior programmability and enables diverse 3D structures. This thesis harnesses the programmability of digital knitting to develop wearable robotic textiles tailored for specific tasks. Setting itself apart from the conventional robotic textile approach, these works emphasize body-conforming geometries and the seamless integration of functional components. Incorporating materials such as actuators, variable stiffness fibers, and sensors, these substrates are engineered to execute precise mechanical movements and detect tailored deformations necessary for specific wearable tasks. What sets robotic textiles apart is the meticulous control over each stitch’s properties, augmented by the strategic use of functional filaments. This approach situates itself in contrast to traditional wearables, which often rely on rigid components ill-suited for accommodating diverse body shapes and movements. This thesis further explores the realm of personalized robotic textiles, presenting a case study that highlights their potential as custom wearable devices fabricated through a design tool, bypassing a learning curve required for digital knitting. This case study demonstrates how robotic textiles can provide users with personalized mechanotherapy. By developing a design tool that eliminates the need for extensive knowledge of digital knitting and involving multiple stakeholders, this research aims to empower designers, regardless of their background in knitting or engineering, to create personalized robotic textiles that seamlessly integrate into everyday life.

@inproceedings{thesis, author = {Kim, Heather Jin Hee}, title = {Leveraging Fabric Substructure Variations of Actuator-Integrated Robotic Textiles for Wearable Applications}, booktitle = {Press}, year = {2024}, }

2023

- ACM CHI

KnitDema: Robotic Textile as Personalized Edema Mobilization DeviceJin Hee (Heather) Kim, Joan Stilling, Michael O’Dell, and 1 more authorIn Proceedings of the 2023 CHI Conference on Human Factors in Computing Systems, Hamburg, Germany, 2023

KnitDema: Robotic Textile as Personalized Edema Mobilization DeviceJin Hee (Heather) Kim, Joan Stilling, Michael O’Dell, and 1 more authorIn Proceedings of the 2023 CHI Conference on Human Factors in Computing Systems, Hamburg, Germany, 2023Hand edema, defined as swelling of the hands caused by excess fluid accumulation, is a pervasive condition affecting a person’s range of motion and functional ability. However, treatment strategies remain limited to time-consuming manual massage by trained therapists, deterring a widely accessible approach. We present KnitDema, a robotic textile device that allows sequential compression from distal to proximal finger phalanges for mobilizing edema. We machine-knit the device and integrate small-scale actuators to envelop granular body locations such as fingers, catering to the shape of the hand. In addition, the device affords customizable compression levels through the enclosed fiber-like actuators. We characterize compression parameters and simulate the shunting of edema through a mock fluid system. Finally, we conduct a case study to evaluate the feasibility of the device, in which five hand edema patients assess KnitDema. Our study provides insights into the opportunities for robotic textiles to support personalized rehabilitation.

@inproceedings{knitdema, author = {Kim, Jin Hee (Heather) and Stilling, Joan and O'Dell, Michael and Kao, Cindy Hsin-Liu}, title = {KnitDema: Robotic Textile as Personalized Edema Mobilization Device}, year = {2023}, isbn = {9781450394215}, publisher = {Association for Computing Machinery}, address = {New York, NY, USA}, url = {https://doi-org/10.1145/3544548.3581343}, doi = {10.1145/3544548.3581343}, booktitle = {Proceedings of the 2023 CHI Conference on Human Factors in Computing Systems}, articleno = {472}, numpages = {19}, keywords = {Compression Device, E-Textile, Hand Edema, Haptics, Rehabilitation Device, Robotic Textile, Wearable Computing}, location = {Hamburg, Germany}, series = {CHI '23}, } - IEEE IROS

Robotic Barrier Construction through Weaved, Inflatable TubesHeather Jin Hee Kim*, Haron Abdel-Raziq*, Xinyu Liu, and 4 more authorsIn 2023 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 2023

Robotic Barrier Construction through Weaved, Inflatable TubesHeather Jin Hee Kim*, Haron Abdel-Raziq*, Xinyu Liu, and 4 more authorsIn 2023 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 2023In this article, we present a mechanism and related path planning algorithm to construct light-duty barriers out of extruded, inflated tubes weaved around existing environmental features. Our extruded tubes are based on everted vine-robots and in this context, we present a new method to steer their growth. We characterize the mechanism in terms of accuracy resilience, and, towards their use as barriers, the ability of the tubes to withstand distributed loads. We further explore an algorithm which, given a feature map and the size and direction of the external load, can determine where and how to extrude the barrier. Finally, we showcase the potential of this method in an autonomously extruded two-layer wall weaved around three pipes. While preliminary, our work indicates that this method has potential for barrier construction in cluttered environments, e.g. shelters against wind or snow. Future work may show how to achieve tighter weaves, how to leverage weave friction for improved strength, how to assess barrier performance for feedback control, and how to operate the extrusion mechanism off of a mobile robot.

@inproceedings{wewavebot, publisher = {Institute of Electrical and Electronics Engineers (IEEE)}, author = {Kim, Heather Jin Hee and Abdel-Raziq, Haron and Liu, Xinyu and Siskovic, Alexandra Young and Patil, Shreyas and Petersen, Kirstin H. and Kao, Hsin-Liu}, booktitle = {2023 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS)}, title = {Robotic Barrier Construction through Weaved, Inflatable Tubes}, year = {2023}, volume = {}, number = {}, pages = {8318-8323}, url = {https://ieeexplore.ieee.org/document/10342190}, keywords = {Snow;Friction;Path planning;Electron tubes;Feedback control;Mobile robots;Intelligent robots}, doi = {10.1109/IROS55552.2023.10342190}, }

2022

- ACM CHI

KnitSkin: Machine-Knitted Scaled Skin for LocomotionJin Hee (Heather) Kim, Shreyas Dilip Patil, Sarina Matson, and 2 more authorsIn Proceedings of the 2022 CHI Conference on Human Factors in Computing Systems, New Orleans, LA, USA, 2022

KnitSkin: Machine-Knitted Scaled Skin for LocomotionJin Hee (Heather) Kim, Shreyas Dilip Patil, Sarina Matson, and 2 more authorsIn Proceedings of the 2022 CHI Conference on Human Factors in Computing Systems, New Orleans, LA, USA, 2022We present KnitSkin, a bio-inspired sleeve that can traverse diverse cylindrical terrains, ranging from a user’s forearm at a wearable scale, to pipes and tree branches at an environmental scale. Fabricated with a machine knitted substrate, the sleeve configures a stepped array of knitted scales that exhibit anisotropic friction. Coupled with the extension of actuators enclosed in the sleeve, the scales enable effective directional locomotion on cylindrical surfaces with varying slopes, textures, and curvatures. KnitSkin’s substrates are characterized by scales whose geometries and materials can be fine-tuned and channels that can accommodate diverse actuators. We introduce the design elements of KnitSkin in which we characterize a series of substrate parameters and their resulting anisotropic behaviors. In evaluating the locomotion, we examine the variables associated with the surface and actuator characteristics. KnitSkin obtains diverse applications across different scales, including wearable interfaces, industrial pipe-monitoring, to agricultural robots.

@inproceedings{knitskin, author = {Kim, Jin Hee (Heather) and Patil, Shreyas Dilip and Matson, Sarina and Conroy, Melissa and Kao, Cindy Hsin-Liu}, title = {KnitSkin: Machine-Knitted Scaled Skin for Locomotion}, year = {2022}, isbn = {9781450391573}, publisher = {Association for Computing Machinery}, address = {New York, NY, USA}, url = {https://doi.org/10.1145/3491102.3502142}, doi = {10.1145/3491102.3502142}, booktitle = {Proceedings of the 2022 CHI Conference on Human Factors in Computing Systems}, articleno = {391}, numpages = {15}, keywords = {Machine Knitting, Mobile Robots, Smart Textiles, Wearable Robots}, location = {New Orleans, LA, USA}, series = {CHI '22}, }

2021

- ACM DIS

KnitDermis: Fabricating Tactile On-Body Interfaces Through Machine KnittingJin Hee (Heather) Kim, Kunpeng Huang, Simone White, and 2 more authorsIn Proceedings of the 2021 ACM Designing Interactive Systems Conference, Virtual Event, USA, 2021

KnitDermis: Fabricating Tactile On-Body Interfaces Through Machine KnittingJin Hee (Heather) Kim, Kunpeng Huang, Simone White, and 2 more authorsIn Proceedings of the 2021 ACM Designing Interactive Systems Conference, Virtual Event, USA, 2021We present KnitDermis, on-body interfaces that deliver expressive non-vibrating mechanotactile feedback on the wearer’s body. Fabricated through machine knitting, they embed shape-memory alloy micro-springs in knitted channels, which deliver tactile sensations on the skin when activated. KnitDermis interfaces take advantage of machine knitting’s shaping properties which allow it to generate slim, stretchable, and versatile forms that can conform to underexplored body locations, such as protruded joints and convex body locations. We introduce a fabrication approach and a series of case studies to design a wide range of form factors, textures, and tactile patterns, including compression, pinching, brushing, and twisting. We conduct a user study to elicit KnitDermis’ effectiveness and wearability on diverse body locations and engage users to unpack envisioned use cases and perceptions towards the interfaces. We draw insights from our extensive research-through-design investigations on the potential of knitting as a soft approach for close-body and expressive tactile interfaces.

@inproceedings{knitdermis, author = {Kim, Jin Hee (Heather) and Huang, Kunpeng and White, Simone and Conroy, Melissa and Kao, Cindy Hsin-Liu}, title = {KnitDermis: Fabricating Tactile On-Body Interfaces Through Machine Knitting}, year = {2021}, isbn = {9781450384766}, publisher = {Association for Computing Machinery}, address = {New York, NY, USA}, url = {https://doi.org/10.1145/3461778.3462007}, doi = {10.1145/3461778.3462007}, booktitle = {Proceedings of the 2021 ACM Designing Interactive Systems Conference}, pages = {1183–1200}, numpages = {18}, keywords = {Tactile Feedback, Shape Memory Alloy, On-Body Interface, Machine Knitting, Haptics}, location = {Virtual Event, USA}, series = {DIS '21}, }

2015

- IEEE HRIIntelligent Product DesignHan Nwi Lee, Yeseul Namkoung, Jinhee Kim, and 10 more authorsIn Proceedings of the Tenth Annual ACM/IEEE International Conference on Human-Robot Interaction Extended Abstracts, Portland, Oregon, USA, 2015

Robot’s appearance types could be classified into human-oriented robot and product-oriented robot. Human-oriented robot resembles human’s appearance and behavior whereas product-oriented robot is an intelligent product that is laden with robotic technologies based on the existing product [1]. In Kwak et al.’s study [1], customers categorized a human-oriented robot as a robot and a product-oriented robot as one of the existing product categories, and a product-oriented robot was more effective than a human-oriented robot for consumers’ evaluation and purchase intention toward robots. On the basis of this, we developed several intelligent products including intelligent slippers, intelligent Christmas tree blocks, an intelligent piggy bank, an intelligent clothespin, an intelligent grass protection mat, and an intelligent frame (see Figure 1).

@inproceedings{intelligent, author = {Lee, Han Nwi and Namkoung, Yeseul and Kim, Jinhee and Lee, Seul and Jeong, Daun and Seo, Hyunji and Park, Soyeon and Lee, Kyeongah and Yang, Sunbin and Choi, Jimin and Kim, Yeeun and Choi, Jung Ju and Kwak, Sonya S.}, title = {Intelligent Product Design}, year = {2015}, isbn = {9781450333184}, publisher = {Association for Computing Machinery}, address = {New York, NY, USA}, url = {https://doi.org/10.1145/2701973.2702694}, doi = {10.1145/2701973.2702694}, booktitle = {Proceedings of the Tenth Annual ACM/IEEE International Conference on Human-Robot Interaction Extended Abstracts}, pages = {301}, numpages = {1}, keywords = {product-oriented robot, intelligent product design, intelligent product, human-oriented robot}, location = {Portland, Oregon, USA}, series = {HRI'15 Extended Abstracts} }